When I left this blog few years ago, I didn't take the time to write on my engine installation after the Titanium firewall was complete! Before getting into other topics, I will just wrap up this chapter first.

It went fairly smoothly since there was no change to the accessories and hoses. Again, I found easier to mount all of them as well as the engine mount while the engine was still on the hoist. Then I could precisely position the FWF assembly against the firewall with the help of my dad and the engine leveler:

While the engine was gone in the shop for repair, I also took the opportunity to modify by exhaust to provide more support. When I bought the airplane, the whole stack was held only by the cylinders, and each time I was pulling Gs, I had this fear of having a cracked exhaust after my flight.

I looked at several attachments on other aircraft, including some fancy ones linked to the engine mount with springs to allow movement... It seemed overly complicated to me since I did have attachment points available directly on the engine oil sump. This didn't require springs since the exhaust is moving with the engine.

I spent quite some time looking at the engine to find the easiest way to hook the exhaust. Took some cardboard to simulate small brackets. I ended up with two brackets, one for each pair of my crossover exhaust.

I gave precise instructions to my welder in order to add two lugs to the exhaust with my desired angles. I then took the exhaust for ceramic coating since I got rid of the fiberglass wrapping and wanted to mitigate the risk of high cowl temps. Once I got everything back in the hangar, I was pleased with the fit of the exhaust with my new SS brackets:

Another fix that helps quite a bit my peace of mind!

One other thing that was long overdue was the making of new baffles. The old ones were patched, cracked and the baffle seal was all dried up.

Never underestimate the amount of time required to make new baffles from scracth... Took me in average a day for each baffle panel. Used all sorts of tools like an air nibbler to make the first rough cut and then a beverly shear for the finish cut. My friend Scott's tools were again very useful!

I used the old baffles as a template basis, with cardboard at some locations where I wanted an extension of the metal to better follow the cowl's inner shape. Lots of trial and errors, but perseverance paid off and I was quite happy with the end result:

Last step was to install the silicone baffling material (that's the fun part). I decided to use #4 screws with heat nuts instead of pop rivets to better control the pressure on the silicone material. This helped minimizing the ripple effect when excessively squeezed.

Once the baffles were finished, I painted them to protect them against corrosion, Reinstalled all panels and cowling, made a good wash to the airplane, weighed it and then went flying!

It felt so good to get back in the air again. Here's a few shots taken by Stephen J. Thorne (awesome photographer) in Gatineau (CYND). Formation was with my friend Peter Ashwood in his beautiful S-1T:

...Now back to 2022 winter! With my house almost done, I can finally get back in airplane mode and I have the following plans for this winter:

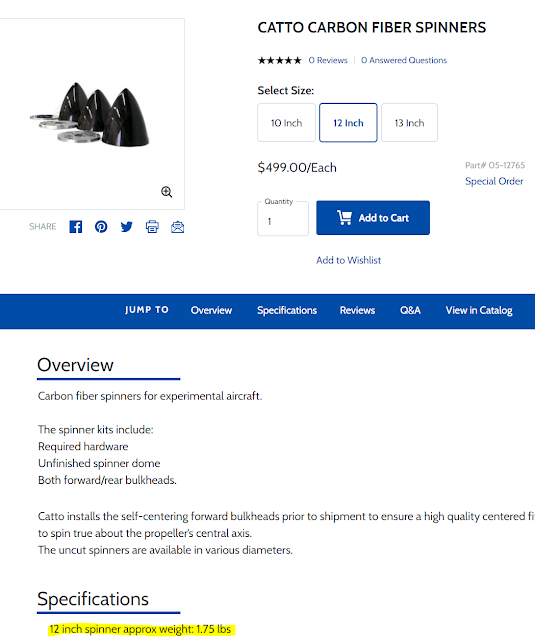

- New Spinner

- New Lexan belly

- Battery relocation

- ELT 406 installation

- AV30 + TailbeaconX installation

That's quite a bit for this winter but hopefully I can get all of this done in time for the spring weather!

Thanks for reading!