The trailing edge extension has been added at some point by one of the previous owners, but I'm not 100% sure why. The most probable cause is that it didn't have the full +7.5/-42 degrees travel recommended in the assembly manual so it was decided to add more surface.

Below is a better shot at the crack. The end of the control horn and the beginning of the trailing edge extension are almost on top of each other. This is certainly the main cause of the crack developing.

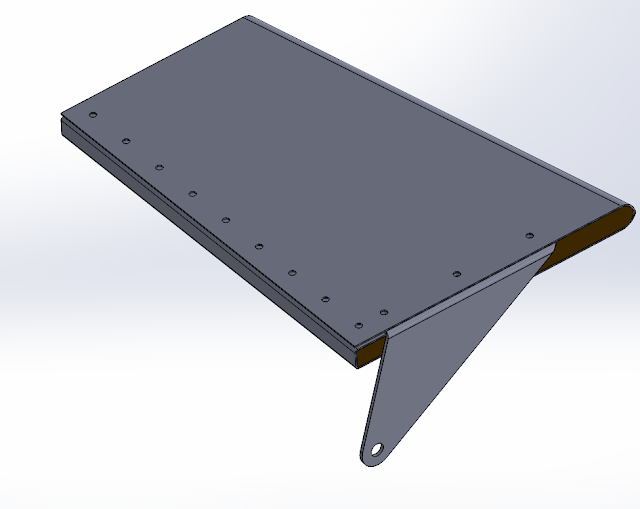

Without knowing the full story behind the trailing edge extension, I decided to err on the conservative side and make a one-piece type trim tab with the same area as the old one:

The brown block behing the control horn is phenolic. I read somewhere that some Pitts Model 12 are made that way and I thought it was a good idea to distribute the load more evenly along the chord of the tab. I also increased the depth of the control horn for the same reasons.

I went to my friend Paul's shop to build the parts. Big thanks to him for his great help! He machined the phenolic block to a perfect fit! The trailing edge bend was not straightforward to do. What we ended up doing is tack weld a rod on the edge of a flat plate and use this as a dye to press the metal sheet between two blocks of steel. I was very happy with the result.

Then I went to see my other friend Scott to use his press drill to make all the required holes. This is probably the most sheet metal work I'm ever going to do on this airplane:

Then I cleaned all the parts and used Alumiprep/Alodyne to create a corrosion protection coat:

Finished the assembly using Avex rivets and AN525 8-32 screws for the control horn:

Next step will be the paint and installation on the airplane!

That new tab looks great!

ReplyDeleteNice Blog

ReplyDeleteSheet Metal Bearing

Friction Rollers

Chain Driven Rollers

Conveyor Manufacturer

Gravity Roller Conveyor Manufacturer

Roller Conveyor Manufacturer

Automatic Film Roll Handling System Manufacturer

Power And Free Roller Conveyor Manufacturer

Flat Belt Conveyor Manufacturers